Seven steps for a perfectly painted Maserati MC20

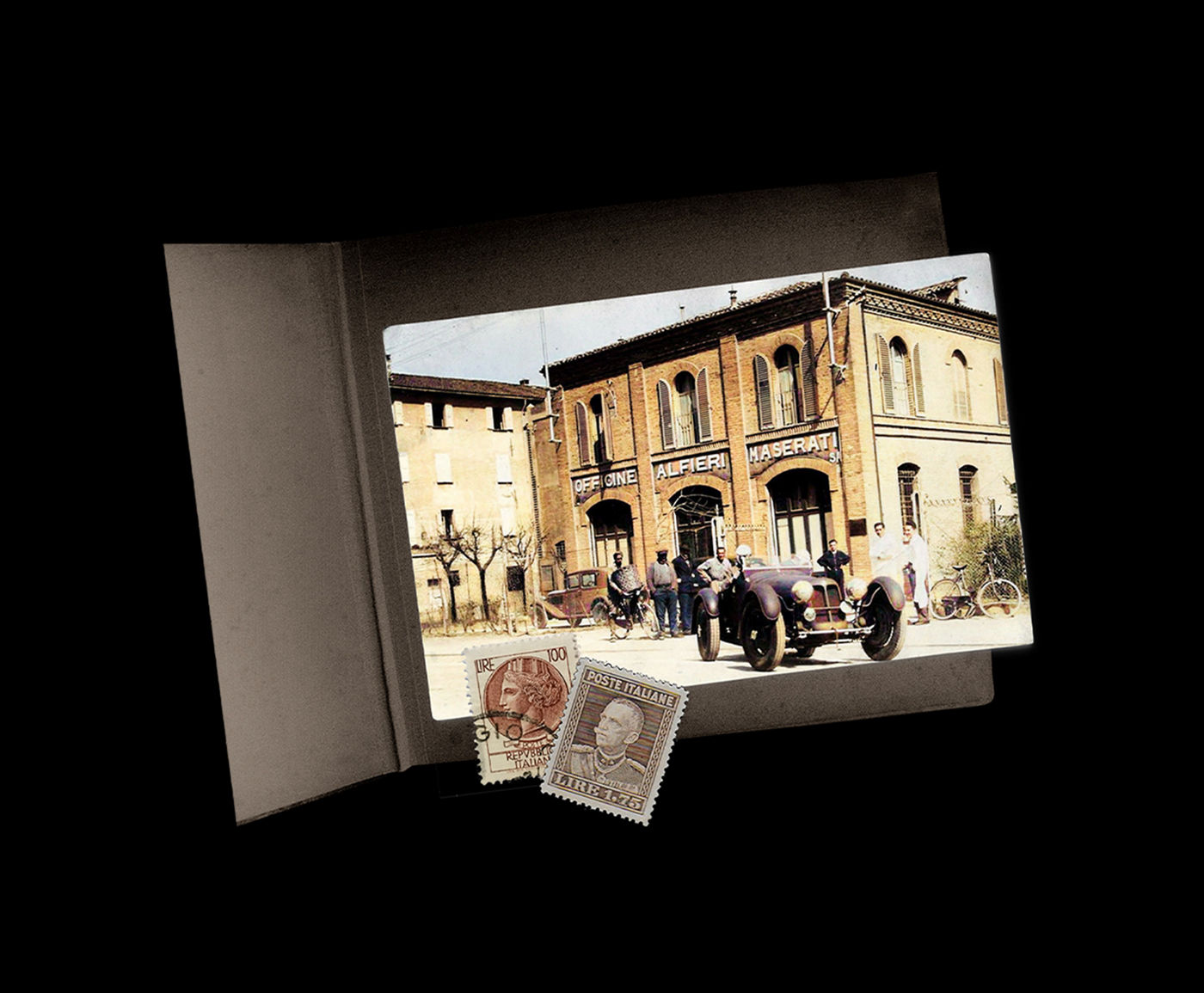

The Maserati site in Modena, modernised to house production of the MC20, now also boasts a completely new paintshop, equipped with innovative, environment-friendly technologies.

The process, carried out at Viale Ciro Menotti for the first time, involves painting of the body together with all its plastic components to ensure perfect colour matching, and adopts paints and process parameters controlled specifically for every application, to ensure the highest quality of the painted product.

It takes the body approximately 20 hours to pass through the various stations of the paintshop: a Maserati MC20 is painted to perfection in seven steps.

The new painting line in detail

The body, complete with all plastic materials for painting, arrives from the metrology room on a transfer trolley, ready to start the various phases of the painting process.

Phase 1

The body enters a preliminary booth where the primer is reactivated.

This operation is done manually and ensures that the product which will be applied subsequently will adhere..

In this phase all internal and external parts of the body not to be painted are covered, as appropriate to the individual car trims.

Phase 2

The body is transferred to the cleaning booth, equipped with deionising guns that neutralise the static electrical charges and clean the surface with ionised compressed air to remove dirt and other contaminants before the next stage of the paint application process.

Phase 3

The body enters the controlled temperature and humidity painting booth, which also has a stable air extraction balance.

Here, two seven-axis robots move around the car, painting the internal and external areas with two main paint layers.

As well as applying the paint, the articulated robots collaborate to open the mobile parts and paint the interiors. While one of them opens the bonnet, the other one sprays paint onto the inside of it and the luggage compartment. The same procedure is followed for the boot lid and the engine compartment.

The robots move in perfect synergy; each one opens a door and then paints the interior and the smaller components on the base of the windscreen. The outside is only painted after these operations are complete.

Phase 4

The body moves on to the first oven station, where it spends approximately 10 minutes at a temperature of 80°C. This stage is necessary to allow evaporation of the water-based components.

After the necessary amount of time has elapsed, the body returns to the painting booth for application of the transparent resin.

Phase 5

The robots perform the same cycle as in phase 3, but this time applying the transparent coating chosen for the car’s package (glossy, coloured or matte).

Phase 6

The body returns to the first oven station, where it spends 15 minutes at 50°C, before moving on to the second oven station, where hardening is completed with 45 minutes at 85°C.

Phase 7

The fully painted body leaves the paintshop ready for removal of the masking, followed by polishing and approval inspection, before proceeding to assembly.

For tri-coat colours and two-tone bodies, the process is repeated with the addition of sanding, cleaning and taping phases.

After painting, quality control staff perform an inspection to assess the look of the painted body with the same attentive eye as a final customer.

The body then returns to the vehicle assembly line.

International

Africa

Europe

America

Asia

Middle-east

Oceania