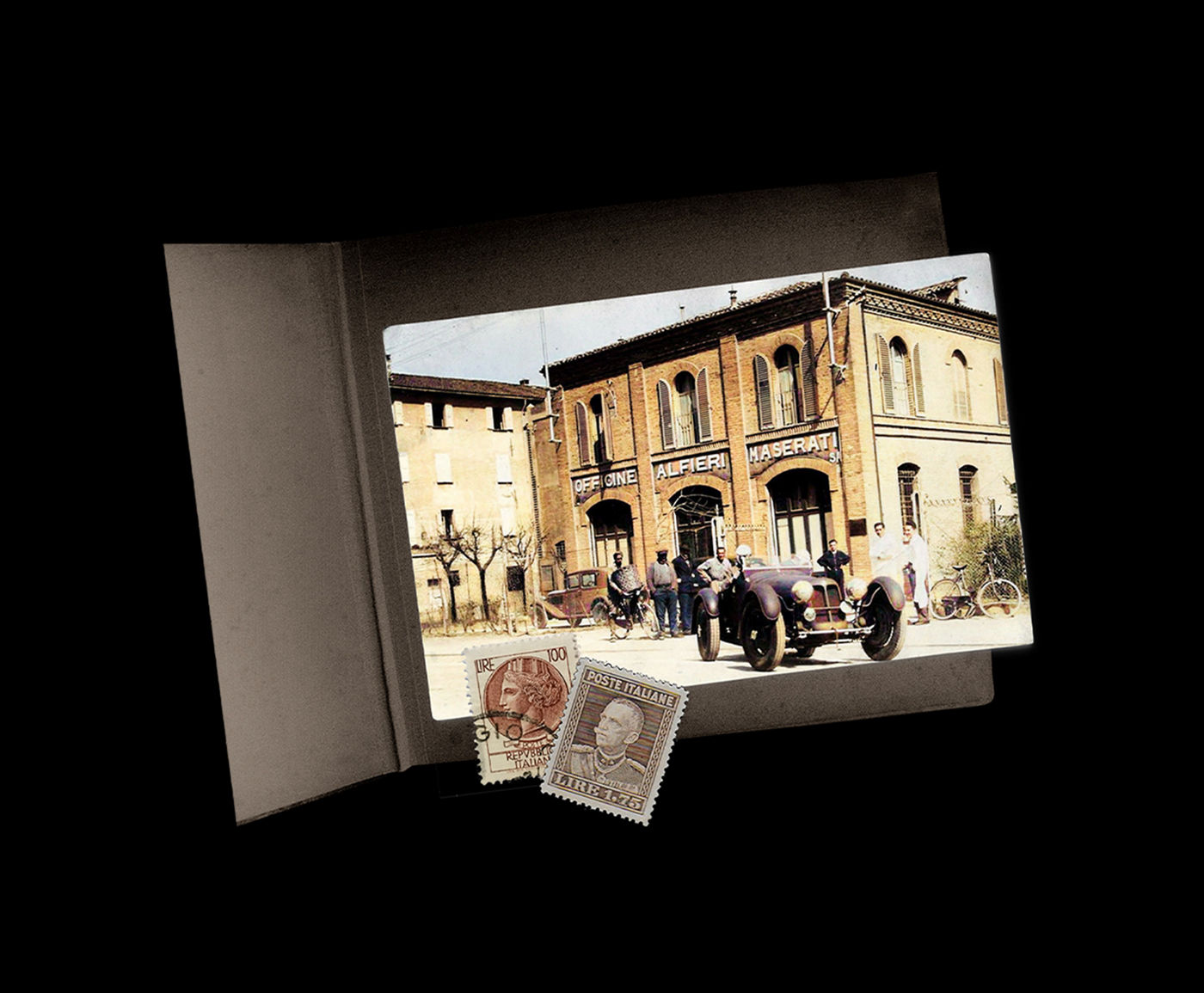

The Maserati Plant in Modena

The historic Maserati plant in Modena has been modernised with new production, engine assembly and painting lines for the MC20 super sports car.

Maserati has chosen the Viale Ciro Menotti plant for the creation of the first car of its new Era.

One of the key innovations implemented in the production hub is the distinctive system which transports the car bodies during the assembly stages (using AGV - Automated Guided Vehicles), which will be the crowning glory of the assembly unit, enabling cars to be conveyed through the process with a high degree of safety and reliability.

Cars are assembled by hand, retaining the craftsmanship for which the Brand is famous. Automation is minimal, with only three robots in the entire system: two to paint the body and one for optimal application of the glue to the windscreen and rear window prior to the delicate assembly phases.

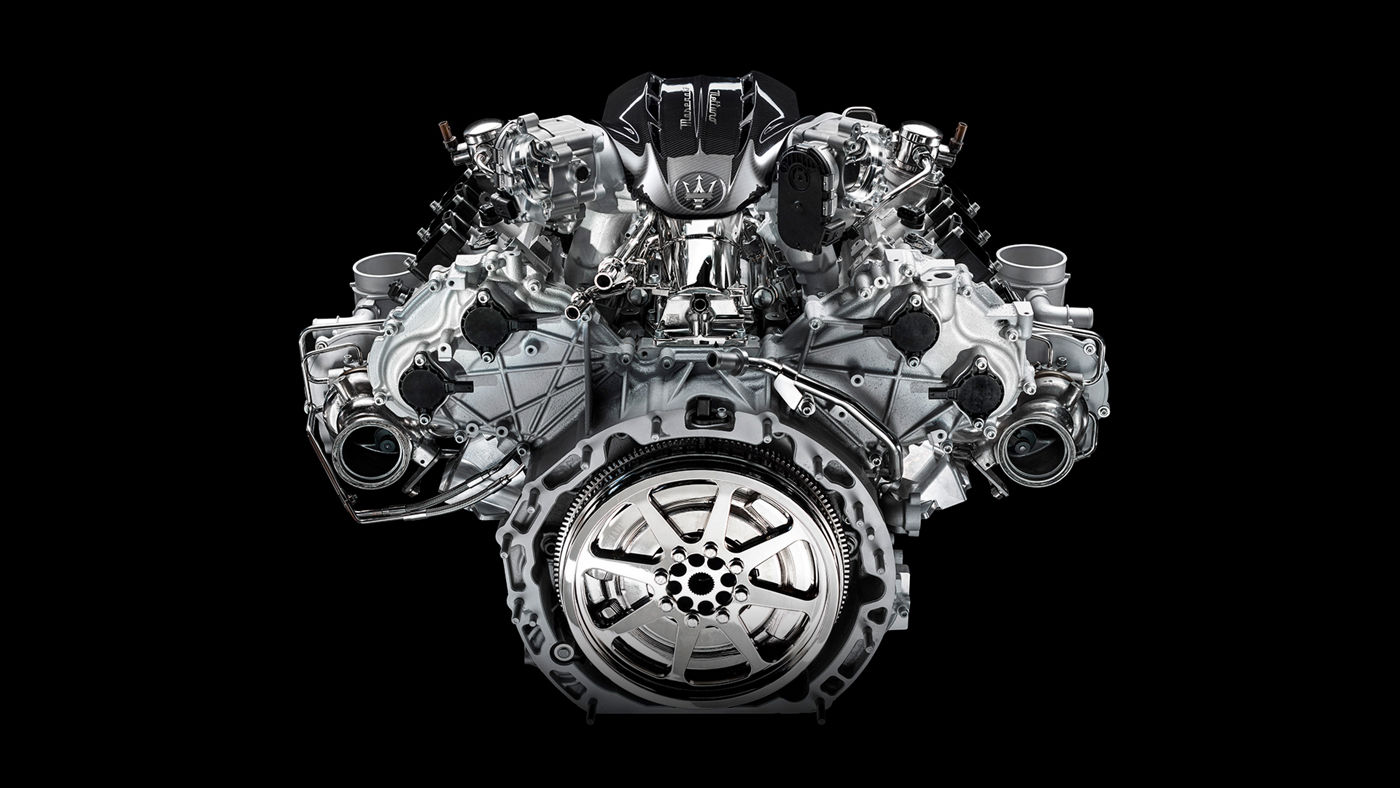

The new production line subdivides into six large areas: body assembly line with metrology area, painting line, engine assembly line, vehicle assembly line with preparation areas, testing line and finishing line.

The plant as a whole comprises more than 70 stations.

The MC20 body assembly line

Aluminium subframes are mounted on the carbon fibre monocoque.

All the external panels are then mounted on this assembly: the roof, the doors, the front and rear wheel arches, the bonnet and the tailgate.

International

Africa

Europe

America

Asia

Middle-east

Oceania